Description

NEG ARG Fibre Glass (Fiber Glass)

ARG Fibre contains high concentration of zirconia, and has both acid resistance and alkaline resistance at high levels. It is mainly used as reinforcement for Glassfibre Reinforced Concrete (GRC) and Calcium Silicate products. It is also used as crack control material for normal concrete and cement mortar. For more than 40 years, it has been widely applied in construction and civil engineering fields.

Chopped Strands

Chopped Strands are produced by cutting strand bundles, which are made of 50 to 200 fine ARG fiber filaments, into various length. It is used as reinforcement for Glassfiber Reinforced Concrete (GRC), Calcium Silicate and Slag Gypsum products. It is also used as crack control material for normal concrete and cement mortar. Its high alkali and acid resistance can be applied to glass fiber papers and filters.

Benefits:

- Insulation

- High Strength

- High Rigidity

- Impact Resistance

- Material Reinforcement

- Water & Weather Resistance (Freeze)

- Chemial Durability (Acid/Alkali)

- Long Life/Ecology

- Non-Inflammability

Product Details

| Property | Unit | |

|---|---|---|

| Thermal Expansion Coefficient | ×10-6/K | 9 |

| Softening point | ℃ | 830 |

| Density | ×103kg/m3 | 2.8 |

| Tensile Strength | GN/m2 | 1.5 |

| Young’s modulus | GN/m2 | 74 |

| Strain to failure | % | 2 |

| Alkali-resistivity, Weight loss (saturated cement solution, 80℃, 200 hours) |

% | ARG Fiber : 0.8 (E Glass Fiber:10.5) |

| Acid-resistivity, Weight loss (10% HCl, 80℃, 90 hours) |

% | ARG Fiber : 1.6 (E Glass Fiber : 42.9) |

| Acid-resistivity, Weight loss (10% H2SO4, 80℃, 90 hours) |

% | ARG Fiber : 1.2 (E Glass Fiber : 42.0) |

※The above values are only advisory, not guaranteed values.

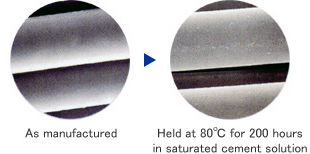

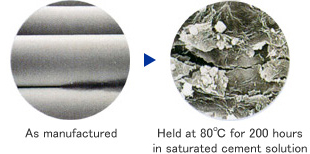

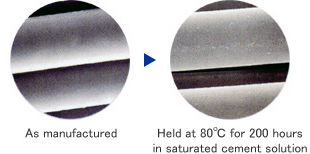

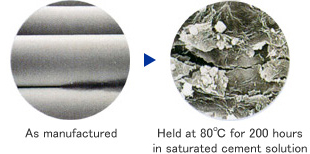

Alkali-resistivityComparison of Alkali Erosive Attack |

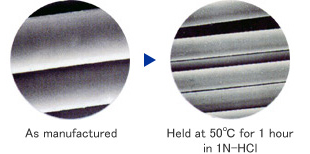

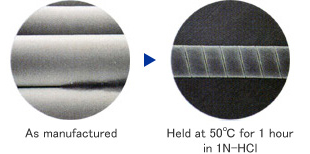

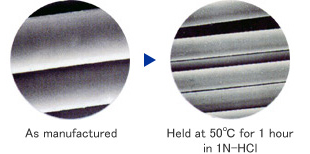

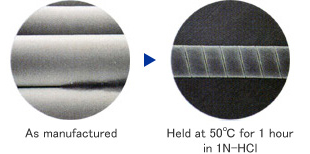

Acid-resistivityComparison of Acid Erosive Attack |

||

| ARG Fiber | ARG Fiber | ||

|---|---|---|---|

Well-nigh perfect Well-nigh perfect |

Well-nigh perfect Well-nigh perfect |

||

| E Glass Fiber | E Glass Fiber | ||

No trace of its original form No trace of its original form |

Damaged at even intervals Damaged at even intervals |

ARG Glass Fibre (Fiber Glass) contains high concentration of zirconia, and has both acid resistance and alkaline resistance at high levels. It is mainly used as reinforcement for Glass fibre Reinforced Concrete (GRC) and Calcium Silicate products. It is also used as crack control material for normal concrete and cement mortar. For more than 40 years, it has been widely applied in construction and civil engineering fields.

Chopped Strands

Chopped Strands are produced by cutting strand bundles, which are made of 50 to 200 fine ARG fiber filaments, into various length. It is used as reinforcement for Glassfiber Reinforced Concrete (GRC), Calcium Silicate and Slag Gypsum products. It is also used as crack control material for normal concrete and cement mortar. Its high alkali and acid resistance can be applied to glass fiber papers and filters.

Benefits:

- Insulation

- High Strength

- High Rigidity

- Impact Resistance

- Material Reinforcement

- Water & Weather Resistance (Freeze)

- Chemial Durability (Acid/Alkali)

- Long Life/Ecology

- Non-Inflammability

Product Details

| Property | Unit | |

|---|---|---|

| Thermal Expansion Coefficient | ×10-6/K | 9 |

| Softening point | ℃ | 830 |

| Density | ×103kg/m3 | 2.8 |

| Tensile Strength | GN/m2 | 1.5 |

| Young’s modulus | GN/m2 | 74 |

| Strain to failure | % | 2 |

| Alkali-resistivity, Weight loss (saturated cement solution, 80℃, 200 hours) |

% | ARG Fiber : 0.8 (E Glass Fiber:10.5) |

| Acid-resistivity, Weight loss (10% HCl, 80℃, 90 hours) |

% | ARG Fiber : 1.6 (E Glass Fiber : 42.9) |

| Acid-resistivity, Weight loss (10% H2SO4, 80℃, 90 hours) |

% | ARG Fiber : 1.2 (E Glass Fiber : 42.0) |

※The above values are only advisory, not guaranteed values.

Alkali-resistivityComparison of Alkali Erosive Attack |

Acid-resistivityComparison of Acid Erosive Attack |

||

| ARG Fiber Glass | ARG Fiber Glass | ||

|---|---|---|---|

Well-nigh perfect Well-nigh perfect |

Well-nigh perfect Well-nigh perfect |

||

| E Glass Fiber Glass | E Glass Fiber Glass | ||

No trace of its original form No trace of its original form |

Damaged at even intervals Damaged at even intervals |

Nippon Electric Glass Co., Ltd (NEG) is considered one of the leading manufacturers of glass fibers in the industry for a few reasons:

- Technological expertise: NEG has a long history of innovation in the glass fiber industry, and has developed advanced technologies for producing high-quality glass fibers.

- Wide range of products: NEG produces a wide range of glass fibers and related products, including E-glass, A-glass, and S-glass fibers, which are used in a variety of applications including construction, transportation, and electronics.

- Global presence: NEG has a global presence with production and sales operations in various countries worldwide. This allows them to cater to the diverse needs of customers and industries.

- Strong Research and Development: NEG has a strong research and development team that is constantly working to improve the quality and performance of their products. This allows them to stay ahead of the competition and meet the evolving needs of customers.

- Quality control: NEG has a strict quality control system in place to ensure that their products meet the highest standards of quality and performance. This helps to ensure customer satisfaction and maintain the company’s reputation for producing high-quality products.

Additional Information

Additional information

| Weight | 2.1 kg |

|---|---|

| Dimensions | 25 × 38 × 11 cm |

| Weight: No selection | 2KG, 5KG, 20KG |