Description

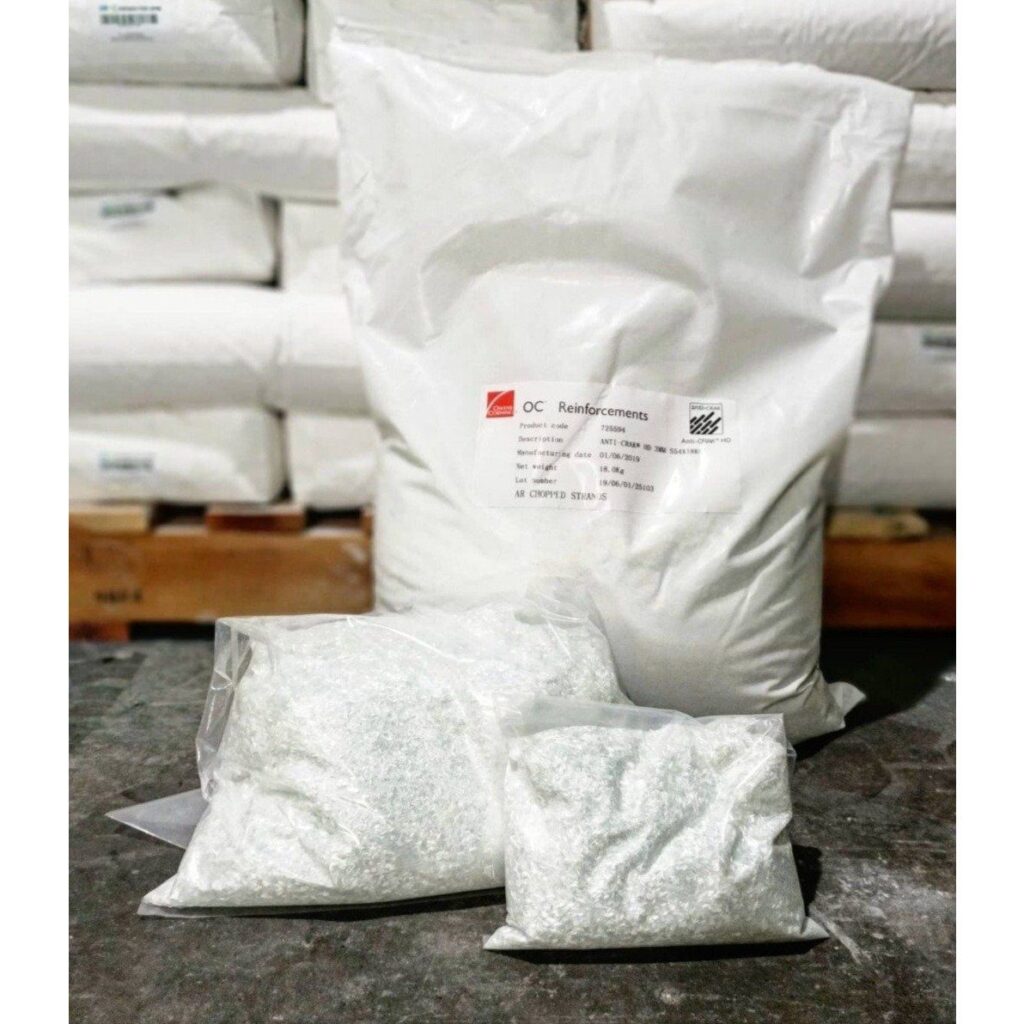

Owens Corning Anti-CRAK 12mm HD Fibres for Concrete Reinforcement (1Kg & 6Kg)

Owens Corning’s Anti-CRAK 12mm HD Fibres for Concrete Reinforcement (6Kg) are a game-changer in the world of Glass Fiber Reinforced Concrete (GFRC). The use of fiber glass as reinforcement in GFRC provides many benefits over traditional steel reinforcement. In this article, we will explore in detail the advantages of using Anti-CRAK HD Fibres, how they work, and why they are a superior choice for enhancing the strength and durability of GFRC.

One of the primary benefits of using fiber glass as reinforcement in GFRC is the increased strength and durability it provides. The unique composition of fiber glass makes it highly resistant to bending, cracking, and other forms of damage. Compared to traditional steel reinforcement, fiber glass is much lighter, making GFRC much easier to handle and transport, and reducing the load on the building’s foundation. Additionally, fiber glass is more flexible than steel reinforcement, allowing GFRC to better withstand movement and thermal expansion.

Another significant advantage of using Anti-CRAK HD Fibres is their resistance to corrosion. Unlike steel reinforcement, fiber glass is highly resistant to corrosion, making GFRC reinforced with fiber glass less likely to degrade over time due to exposure to moisture and other environmental factors. This makes it a more sustainable and environmentally friendly option, as it does not produce any harmful emissions during production. Additionally, fiber glass is a cost-effective option, often less expensive than traditional steel reinforcement. This cost-effectiveness can make GFRC more affordable to produce.

In addition to the above benefits, fiber glass reinforcement also offers greater design flexibility and aesthetics. GFRC reinforced with fiber glass can be made into thinner and more complex shapes than traditional steel reinforced concrete. This allows for more design flexibility, which can add to the aesthetic appeal of the finished product. The invisibility of Anti-CRAK HD Fibres on the finished surface also eliminates the need for additional finishing procedures, saving time and money.

The Anti-CRAK HD Fibres offered by Owens Corning are a top-quality product designed specifically for controlling and preventing cracking in fresh concrete. With a high dispersion rate of 220 million filaments per kg, these fibers are easy to incorporate into mixes and provide excellent workability. Additionally, they are easy to install and do not require any special tools or equipment. The Anti-CRAK HD Fibres are invisible on the finished surface, making them a perfect choice for projects where aesthetics are important.

The use of fibre glass in GFRC provides many benefits over traditional steel reinforcement. With increased strength and durability, improved flexibility, cost-effectiveness, and better resistance to corrosion and environmental factors, it’s no wonder that Anti-CRAK HD Fibres are becoming a popular choice in the GFRC industry. As a sustainable and environmentally friendly option, the use of fiber glass reinforcement is also an attractive choice for those who value sustainability and eco-friendliness in their construction projects.

If you are looking for a superior option for enhancing the strength and durability of your GFRC, look no further than Owens Corning’s Anti-CRAK 12mm HD Fibres for Concrete Reinforcement (1Kg). With their numerous advantages over traditional steel reinforcement, they are a top-quality product that provides excellent results. Whether you are a professional contractor or a DIY enthusiast, the Anti-CRAK HD Fibres are a perfect choice for all your GFRC needs.

There are several benefits of using fiber glass in Glass Fiber Reinforced Concrete (GFRC):

- Strength and durability: Fiber glass provides significant strength and durability to GFRC, making it more resistant to cracking, bending, and other forms of damage.

- Lightweight: Fiber glass is much lighter than traditional steel reinforcement, which makes GFRC much lighter as well. This makes it easier to handle and transport, and it also reduces the load on the building’s foundation.

- Flexibility: Fiber glass is more flexible than traditional steel reinforcement, which allows GFRC to better withstand movement and thermal expansion.

- Corrosion resistance: Fiber glass is resistant to corrosion, which means that GFRC reinforced with fiber glass is less likely to degrade over time due to exposure to moisture and other environmental factors.

- Cost-effective: Fiber glass is generally less expensive than traditional steel reinforcement, which can make GFRC more cost-effective to produce.

- Aesthetics: GFRC reinforced with fiber glass can be made into thinner, more complex shapes than traditional steel reinforced concrete, which allows for more design flexibility and better aesthetics.

- Easy to install: Fiber glass reinforcement is easy to install and does not require any special tools or equipment.

- Environmentally friendly: Fiber glass is a sustainable and environmentally friendly option, it can be recycled and does not produce any harmful emissions during production.

Overall, the use of fiber glass in GFRC provides many benefits, including increased strength and durability, improved flexibility, and cost-effectiveness, aswell as better resistance to corrosion and environmental factors. Additionally, fiber glass reinforcement allows for thinner and more complex shapes to be created, which can add to the aesthetic appeal of the finished product. The ease of installation and recycling, as well as its environmental friendliness, are other benefits that make fiber glass an appealing option for reinforcing GFRC.

Anti-Crak® HD Glass fibres do not protrude through the surface, nor do they require additional finishing procedures.

- Invisible on the finished surface

- Easy incorporation into mixes

- High dispersion (220 million filaments per kg, 100 million per lb)

- Excellent workability

- Does not corrode

- Control and prevention of cracking in fresh concrete

- MSDS

Additional Information

Additional information

| Weight | 1 kg |

|---|---|

| Dimensions | 30.5 × 20.5 × 4 cm |

| Weight: No selection | 1KG, 6KG, 18KG |