How Can You Prevent Cracking in GFRC?

What Causes Delamination, and How Can It Be Avoided?

Delamination threatens the structural integrity of GFRC, causing layers to separate and weaken. This issue typically arises from incorrect mixing, curing, or applying undue stress. At MACt, we emphasise the importance of following rigorous mixing and curing protocols, a key focus of our training sessions, ensuring your GFRC remains intact and robust.

How Does Shrinkage Impact GFRC, and What’s the Solution?

Can Surface Defects in GFRC Be Prevented?

What Leads to Warping in GFRC, and How Can It Be Prevented?

MACt’s Dedication to GFRC Excellence

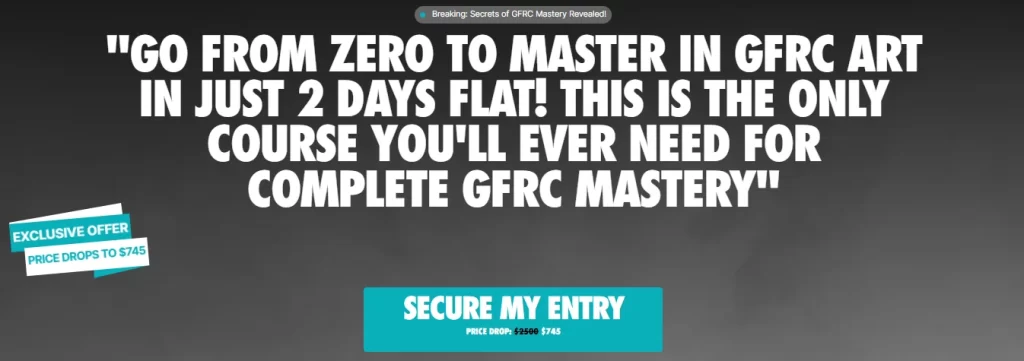

Understanding the intricacies of GFRC manufacturing is crucial for achieving excellence. MACt’s GFRC 2-day training course in Brisbane is designed to equip manufacturers with the knowledge and skills needed to overcome the challenges of GFRC production. Paired with our professional-grade GFRC products, MACt offers a comprehensive foundation for excellence in GFRC applications.

Adhering to best practices, utilising high-quality materials, and gaining expert insights through MACt’s training, you can effectively prevent or mitigate common GFRC challenges. This ensures the success, durability, and aesthetic appeal of your GFRC projects, reinforcing MACt’s commitment to leading the industry in GFRC innovation and quality.