Description

Imer Screed & Mortar Mix 80 Plus 1kw Motor

Forced speed planetary mixers are the best solution to mix premixed or predosed products in bags in an optimal way and with as little effort as possible.

The exclusive I-DUST Dust Grate with an integrated bag breaker placed in a horizontal position, facilitates the loading of bags of material with minimal effort by the operator. When connected to a vacuum, the I-DUST Dust Grate significantly reduces the dispersion of dust in the surrounding environment.

The homogeneity of the mixed product is unmatched, with total absence of lumps of cement in the case of mortars for floor screeds, or of lumps of fibre in the case of fibre-reinforced products.

If necessary, Mix 80 can be used to mix traditional products, with the maximum mixing performance and homogeneity of the mixture.

Suitable for mixing

- Premixed or traditional cement screed, also with the addition of fibres and / or additives

- Lightened screed pre-dosed with expanded clay with grain size <10 mm

(Maximum 1 bag per cycle)

- Self-levelling anhydride / cement-based screeds

- Cement / lime / gypsum-based plasters

- Fibre-reinforced structural plasters also with the addition of additives

- Restorative plasters

- Traditional plasters

- Binders / mortars for injections

- Mortars for reinforcement

- Premixed / traditional bedding mortars

- Filling concrete with grain size <8 mm

- Cementitious adhesives

- Mortars and stuccos for smoothing

- Waterproofing

Operation

The machine must be connected to a vacuum cleaner to limit the dispersion of dust.

Once the machine is turned on using the switch located on the electrical panel, the mixer paddles start to turn clockwise. At this point it is possible to pour the first bag of material by breaking it on the appropriate bag breaker. After adding all the necessary water to the mixture, you can proceed to pour the remaining bag of material into the drum.

The rotation of the paddles moves the material from the bottom upward, and from the centre outward.

A few seconds of waiting is enough to obtain a mixed product without lumps of fibre or concrete balls.

The product can be easily discharged by placing a container under the discharge conveyor and opening the special outlet while the machine is turned on.

Mix 80 can work continuously throughout the day. In case of accidental locking of the paddles, a self-resetting thermal protector will protect the electric motor.

For cleaning at the end of the work, simply pour water into the drum, allowing the paddles to do a first general wash. Once the machine is turned off and the grate is open, cleaning of drum and grate can be completed.

At the end, the residual water can be drained into a container located under the discharge conveyor.

Standard Equipment

- Single-phase gearmotor 230V / 50Hz – Oil bath gearmotor

- Electric safety grate opening

- Self-resetting motor thermal protector

- IP55 undervoltage coil switch and IP67 plug.

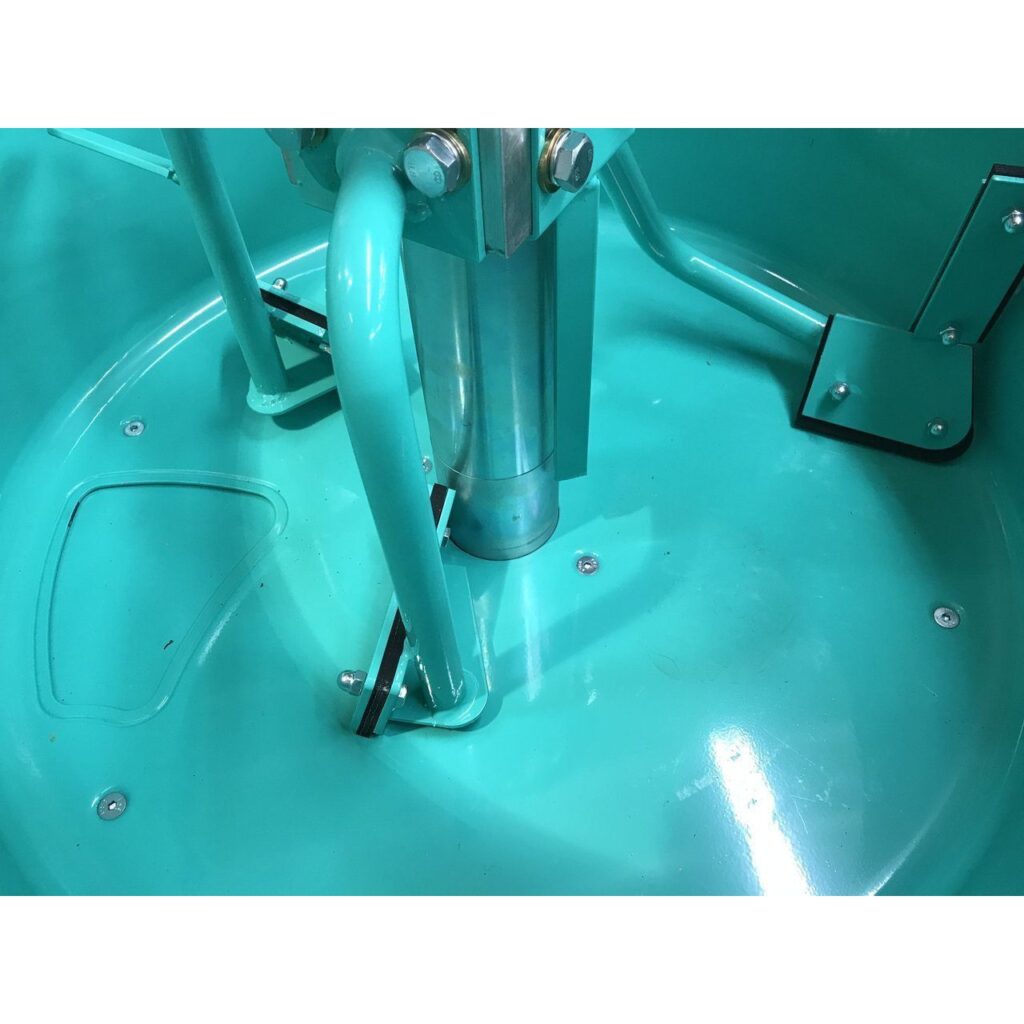

- Grate with bag breaker blade

- Removable handles for handling

- Lifting hooks on 4 sides

- 4 Wheels for handling and loading on the means of transport.

- I-DUST Dust Grate with connector tube for vacuum cleaner

Technical data

- Drum capacity l 80

- Mixing performance l/min 55

- Drum diameter mm 608

- grain size mm 8

- Paddle speed rpm 44

- Electric motor power 230V / 50Hz kW 1

- Absorption A 6.5

- SPL in operator’s position dB(A) 70

- Load / discharge height mm 1156 / 603

- Machine weight (packaging) kg 106(120)

- Dimensions width / length / h mm 660/780/1238

- Packaging dimensions width / length / h mm 730/1280/930

- stackability* 2 (h 1860 mm)

Additional Information

Additional information

| Weight | 150 kg |

|---|---|

| Dimensions | 70 × 133 × 94 cm |